Industrialize & NPI

In the earlier design phase, calculations and 3D designs have shown: the product is manufacturable and functional. Can it be put into production without any objection? No, that creates irresponsible risks. First, a prototype has to be validated, an important step towards making your design ready for series. All the more so because the strict requirements associated with the final product release must be met.

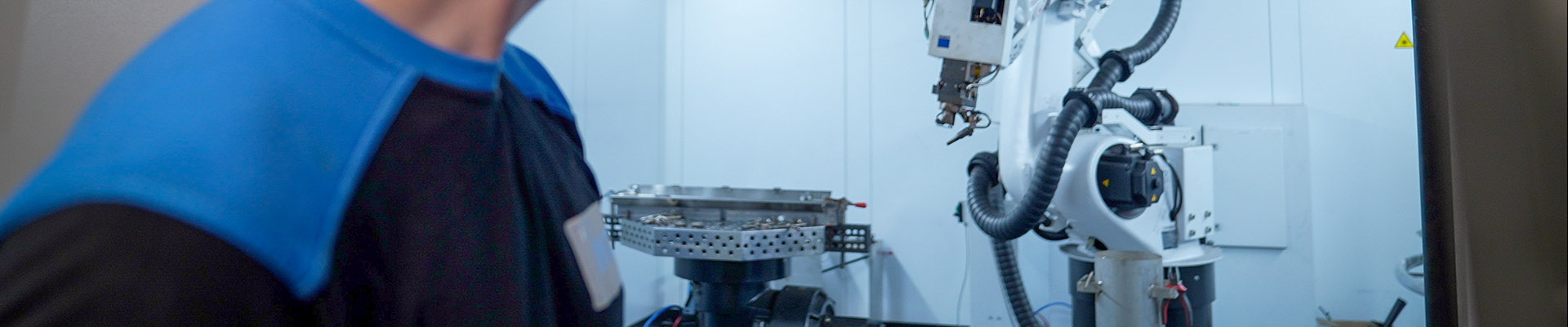

The preparations that characterize this pre-production phase mainly consist of testing the ‘manufacturability’ and the ‘error curve’ of a product. This includes drawing up assembly instructions, test protocols and technology selections. This also includes recording critical dimensions, developing customer packaging and building test setups. Just like taking care of the technical documentation and the construction of pre-production models (PPM).

In all these activities, INNO employees can provide you with a high degree of service. For years in a row they have shown that they master the transition phase from design to production down to the last detail. Technical and strategic. Pays off for you because you can scale so quickly.